IOM keel and rudder mounted

by mark | 22 Nov 2018

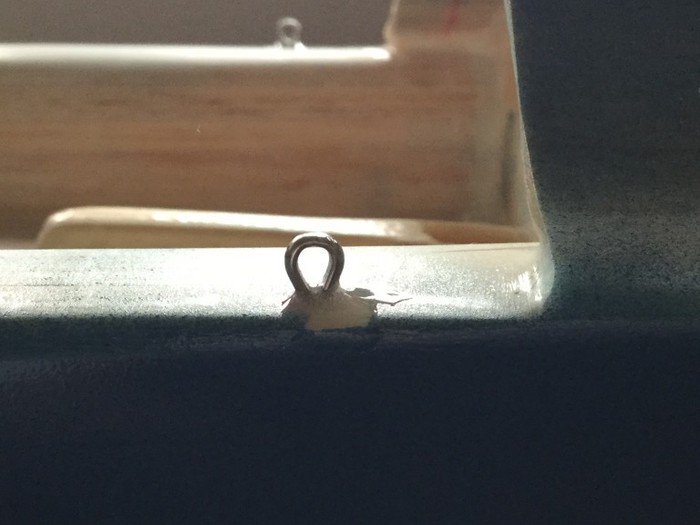

The keel fin is drilled with a bolt nut and shaft epoxied in place. It went easier than expected with no real hiccups.

I also drilled a hole in the rudder for the shaft and epoxied that in. It was difficult to minimize the slot between the rudder and the hull, and I ended up with a bit of a gap. I’m interested in 3D printing a rudder mold where I can mold the shaft in, so I’m content with a gap now and a potential project to replace it later.

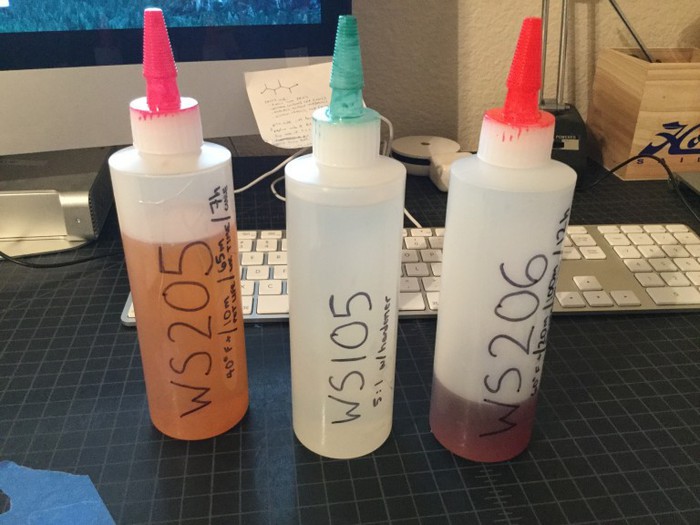

I was nervous about using the Z-Poxy on the rudder, as I’m not confident that it’s waterproof. The rudder doesn’t have a nut holding the shaft in place like the keel does, so any epoxy failure would lose the rudder. I recently fixed a shower scrubby handle with Z-Poxy, and it peeled off rubbery, which makes me worry about all the places I’ve used it on the boat. My favorite part of the Z-Poxy was how easy it is to mix small batches with the squeeze bottles, so I went to the art store and bought some $1 squeeze bottles for my West System epoxy. Much more trustworthy, and handily labeled by Carole!